Submitted by J.M. Andrews on Tue, 23/08/2022 - 14:45

The Concrete Infrastructure Research Group which form part of the Structures Group have published work on the application potential of FRP-Reinforced concrete and the fracture behaviour of functionally layered concrete.

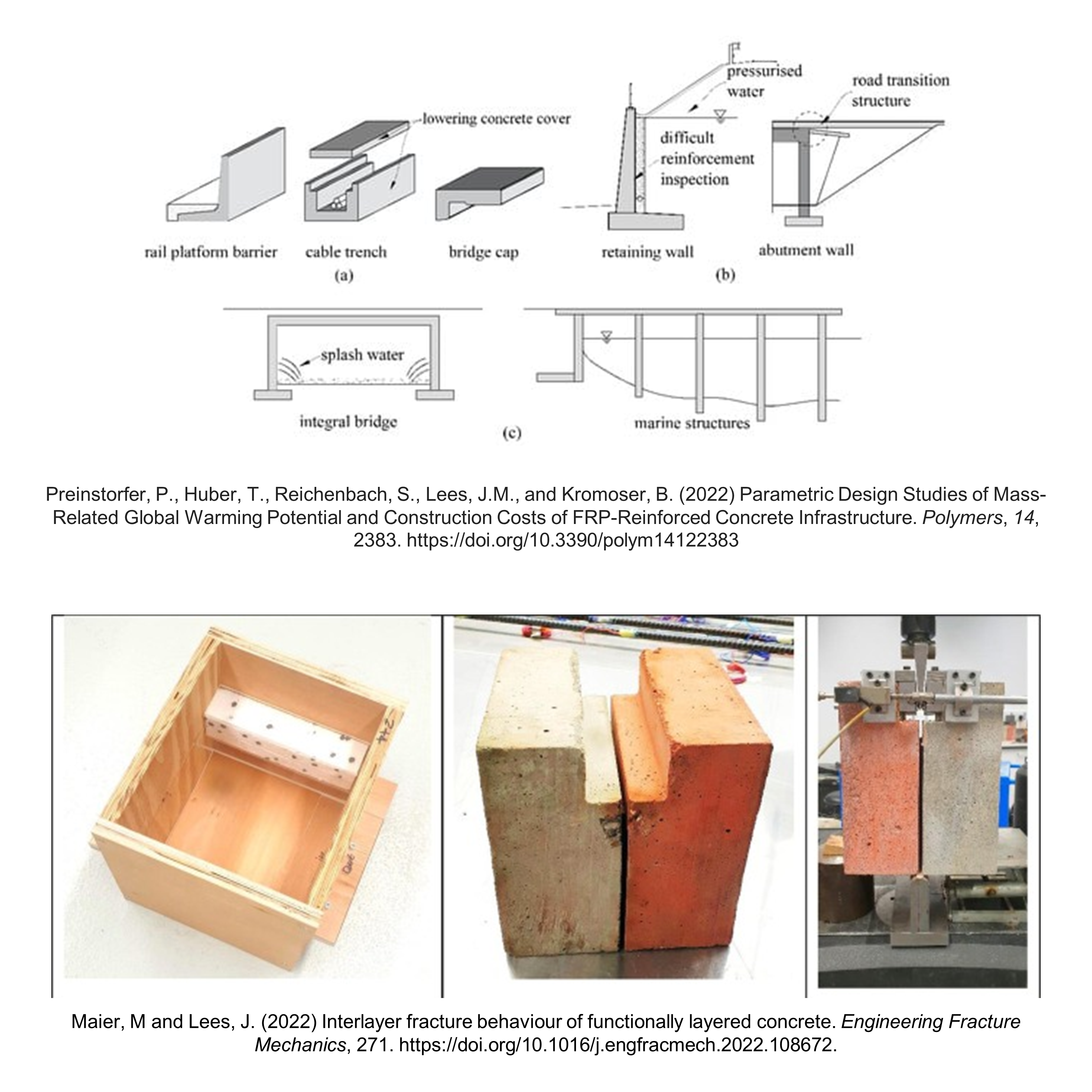

Given that FRP materials are generally more costly and demand greater energy use during production, it is important to understand if the benefits of FRP such as increased performance, outweigh these drawbacks. To achieve this, Concrete Infrastructure Research Group (CIRG) member Philipp Preinstorfer recently performed a parametric design study, assessing the global warming potential and material costs in the construction stage for a range of concrete infrastructure solutions. The study found that the type of structure where the FRP solution is adopted greatly impacts cost competitiveness and emissions. In general, the material costs for FRP solutions are higher than steel-reinforced structures, even when performance is considered. However, for Cradle-to-gate emissions it was found that some FRP options possess a reduced impact.

To find out more about Philipp’s work on the topic, please refer to the published article at this link.

Thanks go to the article collaborators, Tobias Huber, Sara Reichenbach, Benjamin Kromoser, and the head of CIRG, Janet Lees.

Automation and additive manufacturing facilitate more material-efficient options such as structural composite elements and functionally graded elements. The introduction of functional grading introduces the risk of a weak interlayer zone between different concrete layers. Additional uncertainty of this effect is introduced when multi-mix compositions are adopted. CIRG member Marcus Maier recently investigated the behaviour of the interlayer zone by understanding the interlayer fracture properties through wedge-splitting tests. These tests indicated that fracture behaviour in the multi-mix specimens depends on the mix compositions and pour delay time. The study also found that a controlled mix design and fabrication process can mitigate the formation of weak interlayer zones, providing promise for functionally graded options for lower embodied carbon.

To find out more about Marcus’s work on the topic, please refer to the published article at this link.

Thanks go to the article collaborators, the head of CIRG, Janet Lees.

CIRG members continue to provide insights on making concrete more sustainable, please read about our work on our website, and reach out to our members to discuss their research.